As the U.S. ramps up electric vehicle (EV) production and energy storage deployment, one critical question keeps surfacing: how will we meet the surging demand for battery materials? The answer isn’t just in mining more—it’s in recycling smarter. And that’s where modular battery recycling comes in.

At American Li-ion, we’ve adopted modular technology to deliver scalable, fast-to-deploy, and efficient battery material recovery solutions—exactly what America needs to reduce reliance on imports and unlock a secure domestic supply chain.

What Is Modular Battery Recycling?

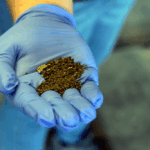

Modular battery recycling refers to compact, self-contained systems designed to recover valuable materials like lithium, cobalt, and nickel from spent batteries. These systems can operate as standalone units or be deployed in groups to expand capacity based on regional or industrial demand.

American Li-ion utilizes Green Li-ion’s patented modular technology, which processes black mass into 99% pure pre-cathode active material (pCAM)—ready to be used by American manufacturers building the next generation of EVs and storage systems.

Why Modularity Matters for the U.S.

The U.S. doesn’t have years to build mega-refineries. EV adoption is surging, and battery plants are coming online at record speed. Modular systems allow battery recyclers to:

- Deploy quickly: Installation timelines are months, not years.

- Scale efficiently: Add capacity as needed without redesigning infrastructure.

- Localize production: Build where the batteries are—reducing transport costs and emissions.

- Control quality: Maintain consistency and purity across multiple sites.

Whether you’re powering a defense hub in the Midwest or supporting a coastal EV gigafactory, modularity means you can build the exact capacity you need, exactly where you need it.

Solving the Supply Chain Bottleneck

The U.S. currently sends much of its battery waste overseas for processing—losing time, money, and control. Modular recycling flips that model by keeping value within American borders.

Instead of relying on high-volume, centralized refining overseas, we can build a decentralized network of U.S.-based recovery units that feed directly into the domestic supply chain. This means less risk, less waste, and more high-purity material in the hands of American manufacturers.

Cost-Effective and Fast to Market

Compared to traditional recycling plants that require tens of millions in CapEx and years of permitting, modular systems are a fraction of the cost and come online in under 12 months. That’s critical for investors and government programs looking for rapid deployment and high ROI.

And because modular systems like ours are plug-and-play, they’re ideal for regional recycling initiatives, DoD applications, and public-private partnerships aimed at accelerating domestic clean-tech infrastructure.

Conclusion: America Needs a Smarter, Faster Recycling Solution

Modular battery recycling isn’t just a technical breakthrough—it’s a strategic one. It empowers the U.S. to respond rapidly to growing material demand, strengthen supply chains, and bring battery production home where it belongs.

At American Li-ion, we’re building the future of recycling—modular, scalable, and made in America.

Explore our modular system and see how it powers American energy independence.