What Full-Circle Battery Recycling Actually Looks Like

Full-circle battery recycling isn’t just a slogan—it’s a process. A process that starts with battery waste and ends with battery-ready materials that can be dropped straight into new manufacturing lines.

Too many recyclers stop halfway. They collect batteries, shred them, and export black mass. That’s not circular—that’s a leak in the loop. At American Li-ion, we go the distance: from spent cells to refined pCAM (precursor cathode active material) made entirely in the United States.

What Is “Full-Circle” Battery Recycling?

It means recovering every usable mineral in a battery and returning those elements back to the supply chain in the exact format manufacturers need. This includes:

- Disassembly and shredding of spent batteries

- Separation and purification of metals

- Production of battery-grade materials like pCAM

- Integration into new battery manufacturing

The goal isn’t just to eliminate waste—it’s to eliminate dependency. That’s what makes it truly circular.

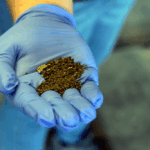

Black Mass Isn’t the Finish Line

Black mass is only the midpoint. It’s a dense mix of valuable metals—but without refining, it’s not usable. Most U.S. recyclers stop here and ship it abroad, where it’s turned into usable materials like pCAM and sold back to U.S. companies.

This approach gives up value, jobs, and control. Full-circle battery recycling demands we go further—domestically.

How American Li-ion Closes the Loop

At our Oklahoma facility, we take in unsorted black mass and produce 99% pure pCAM, ready for integration into new lithium-ion batteries. No overseas shipment. No missing steps. Just a fully domestic system that turns waste into opportunity.

This matters for more than just efficiency—it matters for compliance with U.S. industrial policy, defense requirements, and tax incentives like the Inflation Reduction Act.

The Economic Power of a Closed Loop

Each ton of black mass we refine represents:

- Fewer imports: Domestic pCAM reduces dependence on foreign suppliers

- More jobs: Engineering, operations, QA, and materials science roles

- Lower emissions: No global transport, less energy-intensive mining

And because it’s modular, our system can be deployed in regional hubs—keeping benefits local and accelerating supply chain resilience nationwide.

Why Most Recyclers Aren’t There Yet

Many recyclers aren’t chemical refiners. Their systems aren’t designed to process black mass into battery-grade outputs. It’s a complex challenge that requires advanced materials expertise, patented technology, and a willingness to invest in full-circle capabilities.

American Li-ion was built to meet that challenge—and we’re delivering today, not five years from now.

Why True Circularity Is So Hard to Achieve

Most recyclers lack the technical capacity to refine black mass into battery-grade outputs. According to the Department of Energy, the U.S. is facing a critical shortage of refining capacity for lithium, cobalt, and other battery minerals. Without advanced chemical processing infrastructure, black mass becomes a dead end rather than a beginning.

Organizations like the DOE and White House Office of Science and Technology Policy have made it clear: closing the loop domestically is key to America’s economic competitiveness and climate goals. That’s why American Li-ion is investing in scalable, modular systems that don’t just recycle—but reindustrialize.

Conclusion: Circularity That Delivers

Full-circle battery recycling is more than sustainability—it’s national strategy. It’s how America turns waste into strategic advantage. And it’s the core of what we do at American Li-ion.

Talk to our team to learn how we’re closing the loop for real.