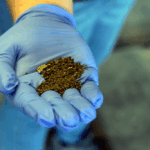

Every lithium-ion battery—once spent—holds untapped potential. Through advanced recycling, American Li-ion is unlocking that value right here in the United States. At the heart of our process is black mass, the residual material left after lithium-ion batteries are shredded. This complex mixture contains valuable metals like lithium, cobalt, nickel, and manganese—elements essential for battery production.

Traditionally, black mass is exported overseas for processing, leaving the U.S. dependent on foreign nations to reclaim these critical materials. American Li-ion changes that. Using Green Li-ion’s patented modular technology, our Atoka, Oklahoma facility transforms unsorted black mass into 99% pure pCAM (pre-cathode active material)—all on American soil. This innovation keeps valuable materials at home and shortens the supply chain, reducing costs and geopolitical risk.

The benefits go beyond national security. Our process is faster and more efficient than traditional hydrometallurgical methods, and it eliminates the need to sort battery chemistries before recycling. That means more throughput, less waste, and battery-ready materials that can be dropped directly into domestic manufacturing pipelines.

As the demand for electric vehicles, energy storage, and electronics accelerates, so does the need for a reliable domestic source of battery materials. American Li-ion is stepping in to fill that gap—transforming waste into value and building a stronger, self-sufficient American battery industry from the ground up.