How Domestic Battery Material Production Fuels National Security

Domestic battery material production is no longer just an economic or environmental priority—it’s a matter of national defense. As the U.S. military and energy systems grow increasingly dependent on lithium-ion technology, securing the materials that power those systems has become a strategic imperative.

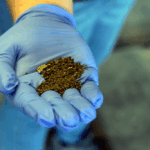

At American Li-ion, we’re helping to meet that challenge by processing black mass into 99% pure pCAM—right here in the United States. Our technology supports energy resilience, industrial self-sufficiency, and defense-readiness at scale.

Why the U.S. Needs Domestic Supply

Today, the vast majority of cathode and anode materials used in U.S. batteries are refined in China or imported through multi-step global supply chains. According to the Department of Defense, these dependencies create unacceptable risks for the military and critical infrastructure.

Modern weapons systems, unmanned vehicles, base communications, and even tactical power supplies all rely on high-density lithium-ion batteries. If the U.S. can’t guarantee the availability of those materials, its ability to operate independently is compromised.

Domestic Battery Material Production = Strategic Advantage

By investing in domestic battery material production, the U.S. creates:

- Military readiness: Ensures secure access to mission-critical power sources

- Industrial resilience: Protects American manufacturers from global disruptions

- Economic sovereignty: Builds high-value industries in key regions

- Policy alignment: Supports Buy American and Defense Production Act priorities

This isn’t just theory. In 2022, the Biden administration authorized DPA Title III funding to ramp up critical mineral processing for national security purposes. American Li-ion’s closed-loop model delivers exactly what those efforts aim to scale.

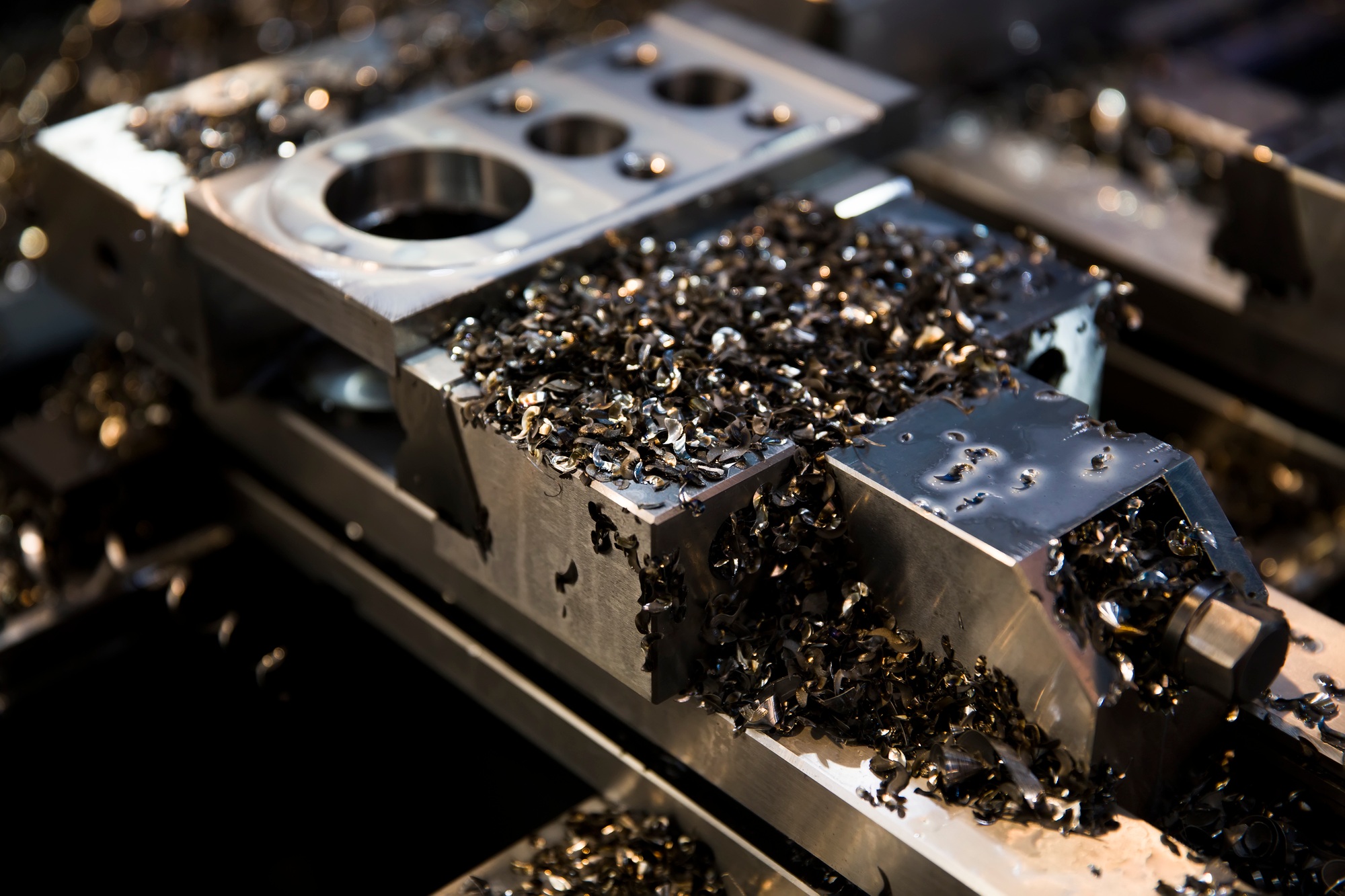

Closing the Loop for the Defense Economy

We don’t just recycle batteries—we create battery-grade pCAM from U.S.-sourced black mass. That means lithium, nickel, cobalt, and manganese refined domestically, ready for use in American-made defense systems, EVs, and grid storage.

This closed-loop process reduces reliance on foreign mines and refineries, shortens supply chains, and protects the IP and performance specs critical to U.S. security operations.

The Cost of Relying on Foreign Minerals

When supply chains break down, readiness breaks down. As global tensions rise, White House guidance has made it clear: securing critical mineral supply is now a national mandate.

American Li-ion’s Atoka facility is already up and running. Our modular expansion model means we can scale output quickly—and anywhere in the country. No waiting. No imports. No compromise.

Energy Independence Is Defense Independence

The more the U.S. can produce domestically, the less it can be held hostage to global disruptions. From EVs to electric naval vessels to drone systems, American innovation needs a secure foundation—and that starts with domestic battery material production.

We’re not just making clean tech work—we’re making it sovereign. That’s why our mission aligns with both the Department of Energy’s blueprint and the Pentagon’s modernization goals.

Conclusion: A Strategic Priority for America

Domestic battery material production is about more than batteries. It’s about resilience, sovereignty, and security. American Li-ion is delivering all three—starting with recycled black mass, ending with defense-ready materials.

Contact our team to explore how your agency, contractor network, or regional authority can partner with American Li-ion to secure tomorrow’s energy supply chain.