Black Mass Recycling USA: America’s Untapped Mineral Reserve

Black mass recycling in the USA is becoming a strategic priority as the nation works to reduce its reliance on imported battery materials. This powdery, dark substance—left over from shredded lithium-ion batteries—may hold the key to securing America’s mineral independence.

At American Li-ion, we’re not just recycling batteries. We’re recovering high-value minerals from black mass and refining them into battery-grade pCAM—on American soil, with American jobs, and at American scale.

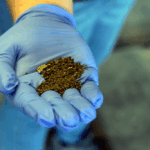

What Is Black Mass?

Black mass is the concentrated mixture of lithium, cobalt, nickel, manganese, and graphite that remains after batteries are shredded and processed for recycling. It’s the richest source of battery minerals currently available in the U.S.—and it already exists within our borders.

Every ton of black mass is a domestic opportunity: a chance to reclaim resources without depending on mining or foreign refining operations. That’s why black mass recycling USA is quickly becoming a cornerstone of domestic energy and manufacturing policy.

America’s Critical Mineral Gap

The U.S. currently imports the majority of its refined battery materials—often from regions where supply chains are unstable or dominated by foreign interests. According to the U.S. Geological Survey, materials like cobalt and graphite are considered critical to national security and manufacturing resilience.

Black mass recycling in the USA helps close that gap. It allows us to reuse the minerals we already have—from EVs, phones, and energy storage systems—without waiting for long-term mining projects to come online.

How American Li-ion Is Leading the Charge

Our facility in Oklahoma is the first in North America capable of processing unsorted black mass into 99% pure pCAM (precursor cathode active material) on-site. Unlike conventional recyclers, we don’t stop at black mass—we go all the way to battery-ready output.

With our patented modular system, we can deploy quickly, scale efficiently, and recover critical materials for American manufacturing needs. Our black mass recycling technology enables localized recovery and closes the loop in the battery supply chain.

How the Process Works

Our system begins with the intake of unsorted black mass, meaning there’s no need to separate battery chemistries. Through a closed-loop chemical process, we isolate and purify the valuable metals—nickel, cobalt, manganese, and lithium. These are recombined into pCAM that meets the purity and consistency requirements of U.S.-based battery manufacturers.

This approach creates more value than simply exporting black mass or selling it to third-party refiners overseas. It keeps high-value materials in circulation—right here at home—and makes the most of every battery we recover.

Strategic Advantages of Domestic Black Mass Recovery

- Faster access to critical materials—no international shipping delays

- Lower emissions and logistics costs compared to import-dependent supply chains

- Support for U.S. manufacturers seeking local, traceable inputs

- Stronger national energy security through domestic sourcing

- Scalable infrastructure that supports battery jobs and regional economic development

Why It Matters Now

With gigafactories on the rise, EV adoption accelerating, and policy support growing, the demand for domestic battery materials is urgent. Black mass recycling USA isn’t a distant idea—it’s a near-term solution that makes use of materials already within our borders. It also reduces dependency on mined raw materials, which are slower to access and harder to scale.

By investing in this type of circular infrastructure now, the U.S. can avoid future supply disruptions and accelerate the deployment of next-generation energy storage systems.

Conclusion: Black Mass Is a Domestic Asset

What others see as waste, we see as opportunity. Black mass isn’t just a byproduct of battery recycling—it’s an untapped mineral reserve waiting to power the next generation of American-made batteries.

At American Li-ion, we’re proving that resource independence doesn’t start in the ground—it starts in the recovery system. Contact our team to learn how we’re turning black mass into American strength through modular, scalable battery recycling technology.