Technology

Empowering the Future with American Li-ion Technology at Our Atoka Facility

What is pCAM?

Precursor cathode active material (pCAM) is a powder-like substance containing critical components such as nickel, cobalt or other chemical elements.

Turning pCAM into Profit

Onshoring pCAM domestic supply chains makes financial sense for businesses and the wider American and European economies.

Our technology extracts

high-quality materials

Our recycled GREENpCAM boasts exceptional characteristics and proven capabilities to meet the evolving needs of batteries.

Battery-grade materials

8 Series NMC

High Nickel Content (80%)

Lower Cobalt (10%)

Improved Energy Density

5 Series NMC

Balanced Performance

Moderate Cobalt Reduction (20%)

Improved Energy Density Over Older NMCs

6 Series NMC

Higher Energy Density than NMC 532

Lower Cobalt Content

Trade-off Between Energy Density & Stability

1 Series NMC

Equal Distribution of Metals

High Cobalt Content

Lower Energy Density Compared to

Newer NMC Chemistries Longer Cycle

Life and Good Thermal Stability

9 Series NMC

Ultra-High Nickel Content

Extremely Low Cobalt Content

Challenges with Thermal Stability

Best Energy Density Among NMC Variants

Li2CO3

Cathode Material Precursor

Critical for EV batteries

Custom NMC

Custom NMC (Nickel Manganese Cobalt) lithium-ion batteries refer to modified or optimized ratios of Nickel (Ni), Manganese (Mn), and Cobalt (Co) beyond the standard NMC 111, 532, 622, 811, and 9½½ formulations. These custom chemistries are designed for specific performance, safety, cost, or sustainability requirements.

American Li-ion’s technology closes the loop on the current recycling process

250-300

60,000 MT

$600M

Our technology accelerates the current recycling process

Accelerating the recycling process and lowering costs, our technology takes black mass and moves directly to produce pCAM (precursor cathode active material), anode-grade graphite, and lithium carbonate (Li2CO3).

As the demand for lithium-ion batteries accelerates, so does the urgency for America to secure its own supply of critical battery materials. Project Lazarus, American Li-ion’s flagship expansion, answers that call—bringing the largest domestic battery materials production facility in North America to McAlester, Oklahoma.

This 150,000-square-foot plant will process 60,000 metric tons of material annually, converting black mass into high-purity cathode and anode materials. At full capacity, Project Lazarus is projected to generate $600 million in annual revenue and create 250–300 high-paying jobs for American engineers, chemists, technicians, and operations staff.

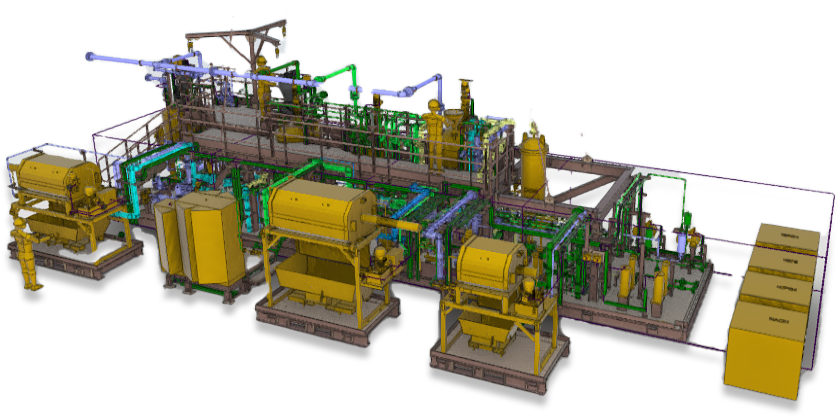

What sets Project Lazarus apart is its foundation on Green Li-ion’s patented modular recycling technology, a globally proven process that transforms unsorted black mass into 99% pure pCAM. By implementing this advanced system on U.S. soil, American Li-ion is reducing dependence on foreign supply chains and empowering manufacturers with clean, battery-ready materials—made in America.

In addition to its core production capabilities, Project Lazarus will serve as a logistics and shipping hub for our Atoka facility, ensuring a seamless, scalable operation across Oklahoma. This expansion is more than growth—it’s a strategic investment in America’s energy future, workforce, and national resilience.

The GLMC-1

The GLMC-1 efficiently transforms spent batteries into battery-grade materials, providing precision and efficiency tailored for small but scalable demand.

GL LFP

The GL LFP converts spent batteries into high-quality Iron Phosphate, delivering precision and efficiency ideal for addressing small-scale yet expandable demands within battery production.